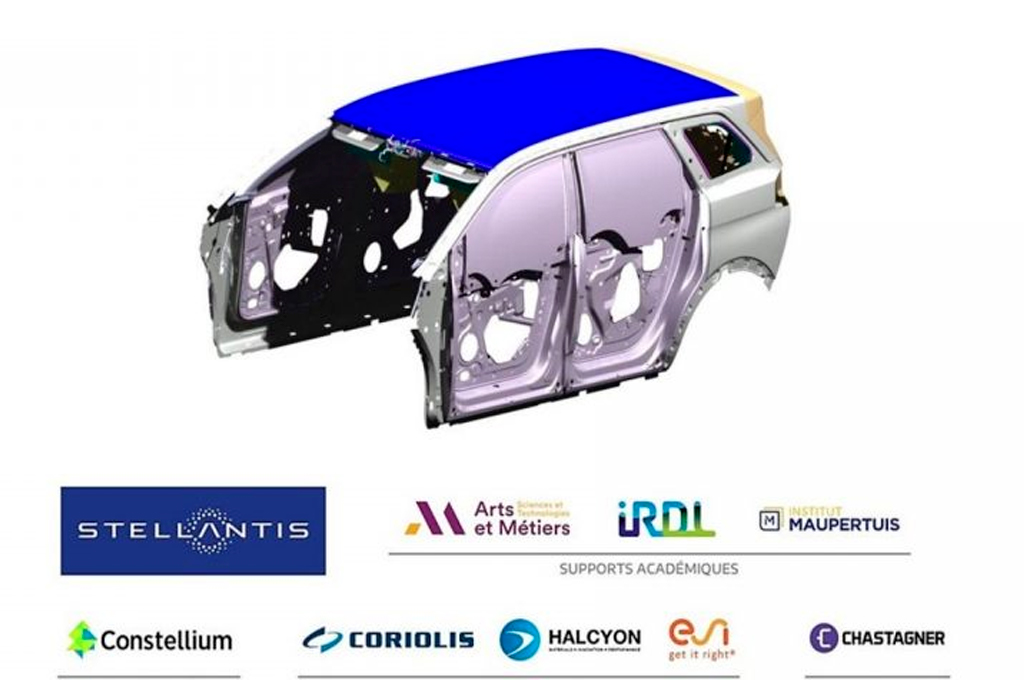

HALCYON, EXPERT DANS LE DOMAINE DES PANNEAUX SANDWICHS COMPLEXES EN NID D’ABEILLE ALUMINIUM

Depuis la conception jusqu’à l’industrialisation, nous adaptons notre technologie du sandwich aluminium à vos pièces techniques.

Les avantages des structures sandwichs en nid d’abeille aluminium :

- Gain de masse pour des propriétés mécaniques identiques

- Diminution des pertes de matières premières

- Recyclabilité de l’aluminium

- Innovation pour les pièces 3D ayant des formes complexes

- Process adaptable aux petites, moyennes et grandes séries

L’INNOVATION HALCYON

Très répandues dans les industries du transport, les pièces en nid d’abeille se composent de 2 peaux ayant de bonnes caractéristiques mécaniques, et d’une âme légère. Ces 2 matériaux combinés permettent d’obtenir des structures légères avec de très bonnes propriétés mécaniques.

Cette technologie était pourtant jusqu’à maintenant limitée à des pièces simples et planes. Mais aujourd’hui, grâce au brevet déposé par Halcyon, toutes les géométries de pièces s’adaptent à cette technologie !

Grâce à notre expertise en formage et en usinage du nid d’abeille aluminium, nous réalisons des pièces complexes, pour répondre aux besoins de nos clients. Qu’elles soient cylindriques, coniques ou à doubles courbures, nous garantissons une précision et une qualité exceptionnelles, tout en optimisant le poids et la résistance des pièces. Notre savoir-faire nous permet d’adapter nos méthodes de production aux spécificités de chaque projet.

Aujourd’hui, Halcyon est le seul industriel capable de former des panneaux sandwichs complexes avec des peaux en aluminium et une âme en nid d’abeille aluminium. Cette innovation offre une alternative intéressante aux matériaux composites à fibres, notre matériau étant recyclable et présentant des coûts de production plus compétitifs.